Rotary Borings Dryers

EnviroAir Rotary Borings Dryers are used to dry and de-oil wet, contaminated chips from machining operations for improved safety in remelting operations and to reduce contamination in the recycled material. EnviroAir offers nine standard models ranging from 5 to 300 cubic feet of chips per hour.

Advantages of EnviroAir Rotary Borings Dryers:

- Indirectly heated – no flame impingement on chips that could cause surface oxidation

- Fully automatic system – simple to operate

- Robust, simple design – low maintenance

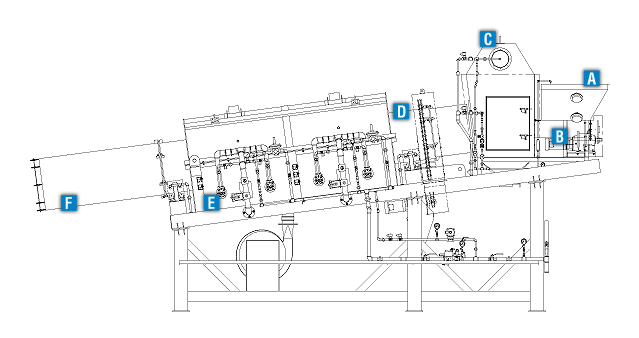

Rotary Borings Dryer Process Diagram

Chips from machining operations are fed into the input hopper.

Screw feeder feeds the chips into the rotary retort.

Exhaust gases, smoke and dust particles are collected in the smoke hood and then discharged to the air quality control system.

Chips are heated to 800 to 900°F inside the rotary retort evaporating the water and oil on the chips.

Gas-fired burners heat the retort from the outside. This indirect heat prevents flame impingement on the chips that could cause surface oxidation.

Dried chips exit the rotary retort and enter the rotary cooling section where the chips are cooled to approximately 300 to 400°F using room air.

- Chips from machining operations are fed into the input hopper.

- Screw feeder feeds the chips into the rotary retort.

- Exhaust gases, smoke and dust particles are collected in the smoke hood and then discharged to the air quality control system.

- Chips are heated to 800 to 900°F inside the rotary retort evaporating the water and oil on the chips.

- Gas-fired burners heat the retort from the outside. This indirect heat prevents flame impingement on the chips that could cause surface oxidation.

- Dried chips exit the rotary retort and enter the rotary cooling section where the chips are cooled to approximately 300 to 400°F using room air.

Air Quality Control System

EnviroAir will furnish a complete air pollution control system for your rotary borings dryer that will meet EPA and local air quality control standards.

A typical pollution control system includes:

- Cyclone for removing large particulate

- Thermal oxidizer for destroying oil vapor and smoke

- Heat recuperator (shell and tube heat exchanger) for preheating the exhaust gases entering the thermal oxidizer to reduce fuel costs

- Baghouse for removing fine particulate

Auxiliary Equipment

EnviroAir will design and furnish a complete chip processing system to meet your chip drying requirements.

Typical dryer infeed equipment may include:

- Infeed chip hopper

- Chip wringer to provide uniform moisture content

- Chip storage silo

- Screw conveyors, bucket elevators and belt conveyors

Typical equipment at the dryer discharge includes:

- Bucket elevator for lifting and cooling the chips

- Vibratory pan feeder to distribute chip

- Double drum magnetic separator

- Vibratory screen separator to remove fines