Thermal Sand Reclamation

EnviroAir Thermal Sand Reclamation Systems reduce the amount of new sand purchased, the amount of waste sand going to landfills, and the associated transportation costs. EnviroAir offers six standard models ranging from ¼ to 6 tons per hour.

EnviroAir Thermal Sand Reclamation Systems feature:

- Low operating cost – less than $7.00 per ton

- Stronger molds and cores

- Improved casting quality

- Fully automatic system – minimal manpower to operate

- Robust, simple design – low maintenance

- No cooling tower to maintain

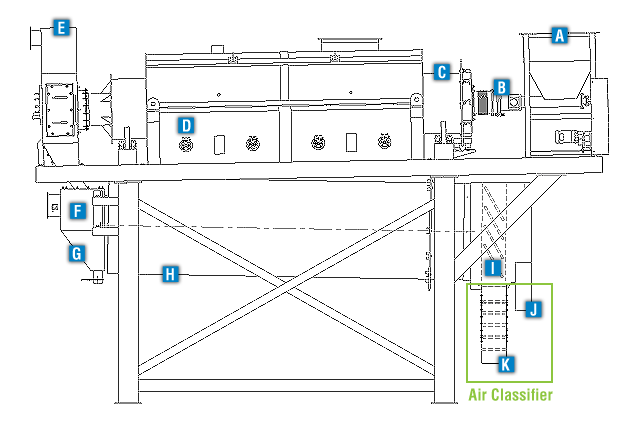

Thermal Sand Reclamation Process Diagram

Waste foundry sand is fed into the input hopper by a conveyor, elevator or pneumatic transporter.

Sealed screw feeder feeds the sand at a constant rate into the rotary retort.

The waste sand is heated to 1,200 to 1,500°F inside the rotary retort evaporating moisture and oxidizing organic binders.

Gas-fired burners heat the retort from the outside. This indirect heat prevents flame impingement on the sand grains.

Retort exhaust gases are collected in the retort exhaust hood and discharged to a dust collector.

Transfer Chute

Cooling air is collected in the cooling drum exhaust hood and discharged to a dust collector.

Heat from the reclaimed sand is transferred to the cooling air in the rotary cooling drum. Sand leaves the cooling drum 10 to 30°F above ambient temperature.

Reclaimed sand is filtered through a 20-mesh screen on the end of the cooling drum.

Metal and other oversize materials flow over the filter screen and out the reject chute.

Reclaimed sand flows through the air classifier to remove fines.

- Waste foundry sand is fed into the input hopper by a conveyor, elevator or pneumatic transporter.

- Sealed screw feeder feeds the sand at a constant rate into the rotary retort.

- The waste sand is heated to 1,200 to 1,500°F inside the rotary retort evaporating moisture and oxidizing organic binders.

- Gas-fired burners heat the retort from the outside. This indirect heat prevents flame impingement on the sand grains.

- Retort exhaust gases are collected in the retort exhaust hood and discharged to a dust collector.

- Transfer Chute

- Cooling air is collected in the cooling drum exhaust hood and discharged to a dust collector.

- Heat from the reclaimed sand is transferred to the cooling air in the rotary cooling drum. Sand leaves the cooling drum 10 to 30°F above ambient temperature.

- Reclaimed sand is filtered through a 20-mesh screen on the end of the cooling drum.

- Metal and other oversize materials flow over the filter screen and out the reject chute.

- Reclaimed sand flows through the air classifier to remove fines.

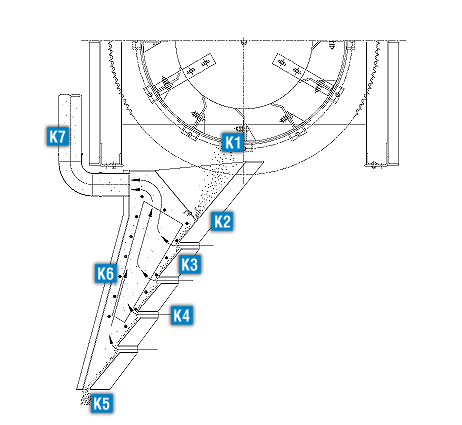

Air Classifier Process Diagram

Screened openings in the cooling drum filter reclaimed sand into the air classifier.

Adjustable slot in classifier infeed hopper to distribute the sand across the classifier.

Sand flows down inclined surface inside the classifier.

Room air enters the classifier through the cascading sand to remove unwanted fines from the reclaimed sand.

Reclaimed sand drops from classifier into a conveyor or pneumatic transporter.

Sand fines are captured in the upward moving airflow and are exhausted from the classifier.

Classifying air and fines are discharged to a dust collector. A damper is provided to adjust the classifying air flow rate to control the AFS fineness number of the reclaimed sand.

- Screened openings in the cooling drum filter reclaimed sand into the air classifier.

- Adjustable slot in classifier infeed hopper to distribute the sand across the classifier.

- Sand flows down inclined surface inside the classifier.

- Room air enters the classifier through the cascading sand to remove unwanted fines from the reclaimed sand.

- Reclaimed sand drops from classifier into a conveyor or pneumatic transporter.

- Sand fines are captured in the upward moving airflow and are exhausted from the classifier.

- Classifying air and fines are discharged to a dust collector. A damper is provided to adjust the classifying air flow rate to control the AFS fineness number of the reclaimed sand.

Related:

Foundry Sand and Waste Foundry Sand (WFS) Management Challenges